Please see below for the indepth information on various print features offered by RockDesign.

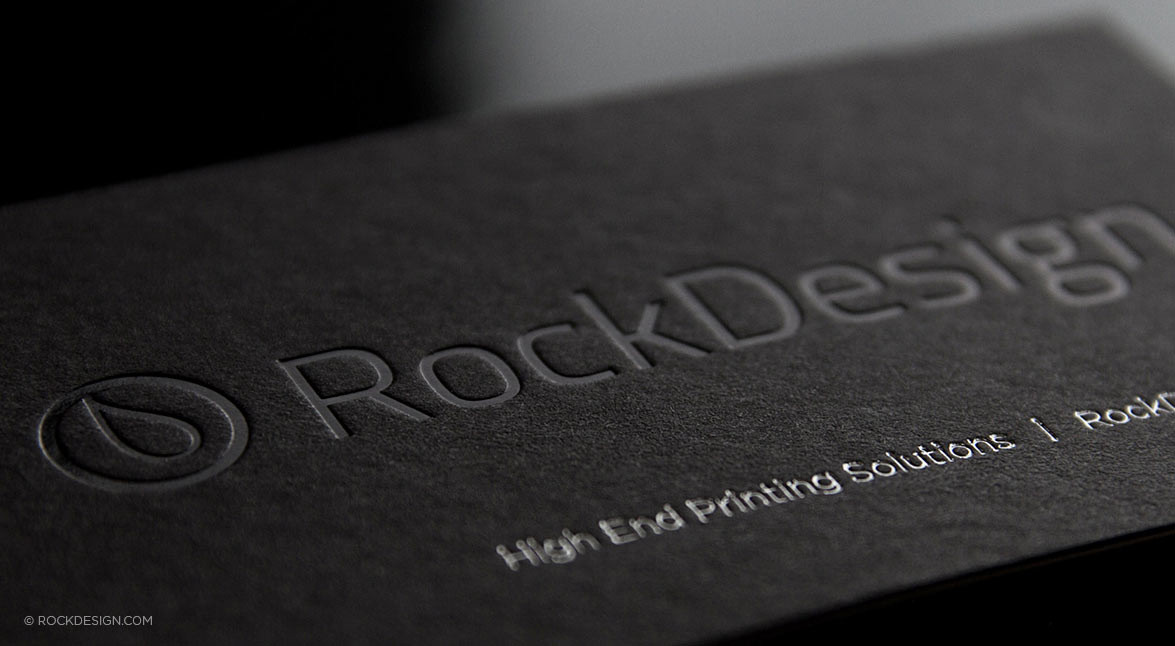

Emboss is a plate stamping process that results in a design element being pushed through the card. Because of this, one side of the design will have a raised effect while the other will have a debossed (pushed-in) appearance. Emboss can also be combined with foil stamp or ink printing, such as offset, to add an accent of color. When designing a card with an emboss, please allow for space on the both sides of the card since each will be affected.

.jpg)

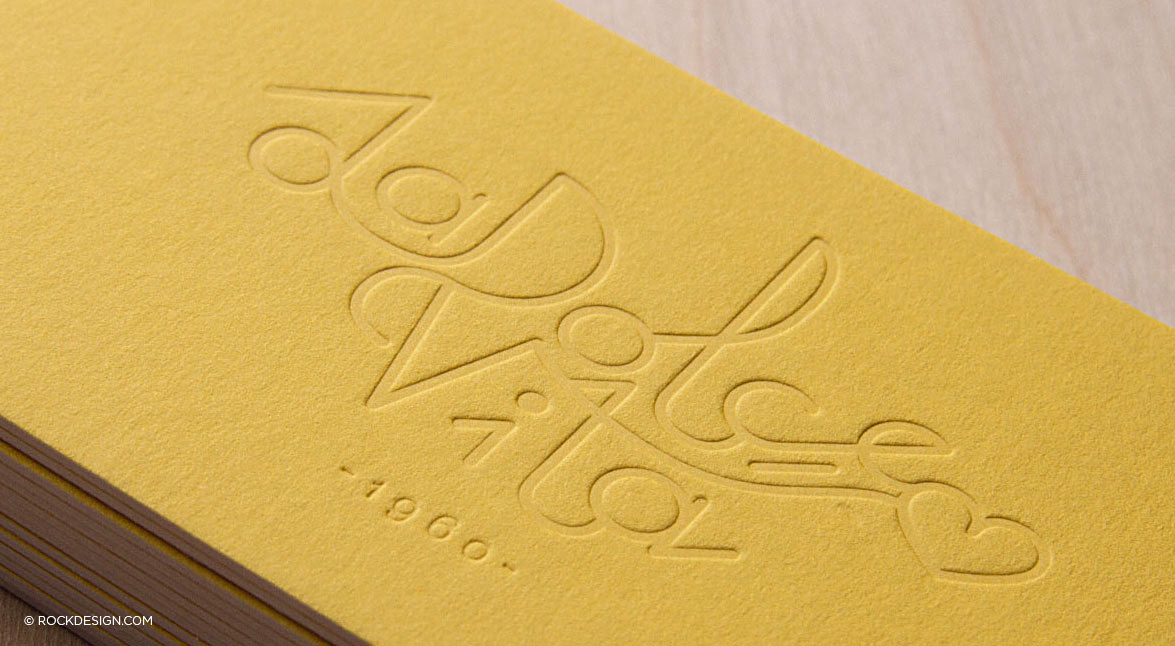

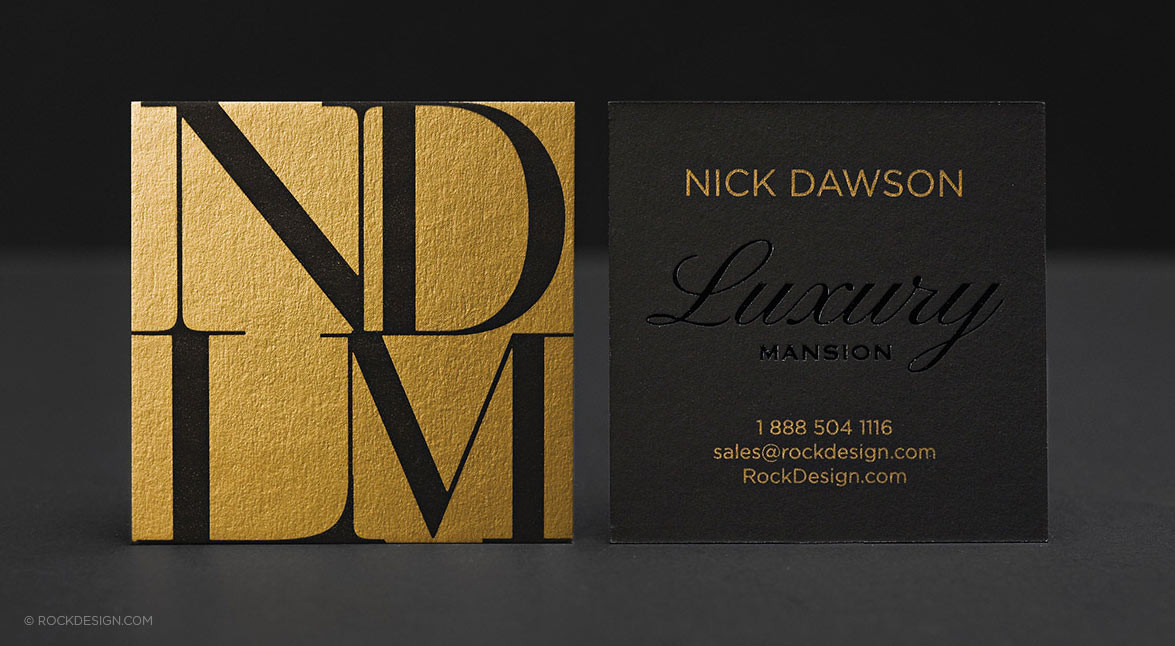

Debossing is another one of our plate stamping processes. Unlike an emboss, where enough pressure is applied to push through the cardstock, a deboss has only enough pressure used to create an indented look. This finishing can be combined with foil or ink printing to create further definition of a design, or can be left blind for a subtler appearance. Debossing can generally be applied to any paper cardstock above 25pt in thickness, but not to our Soft Suede or Silk Laminated.

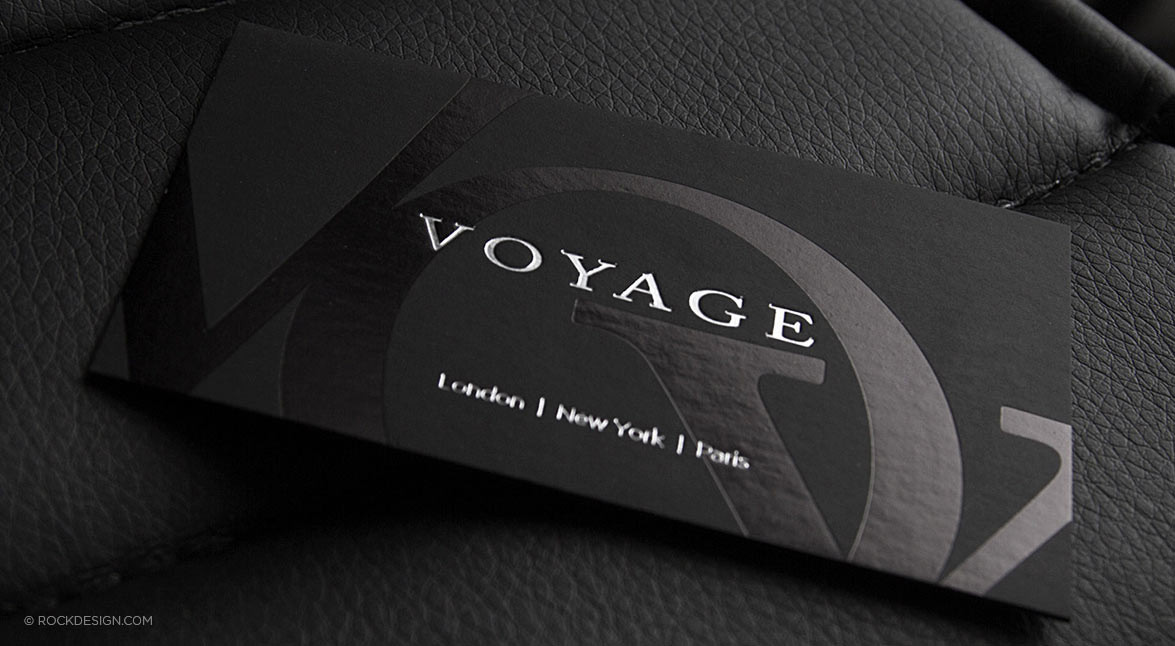

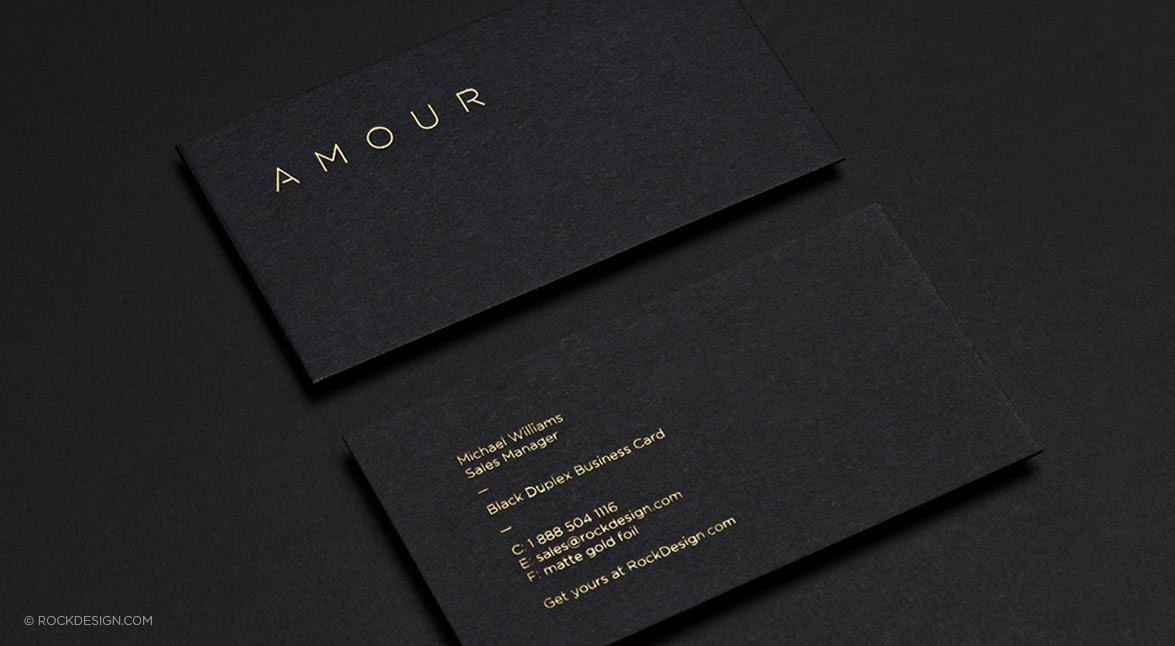

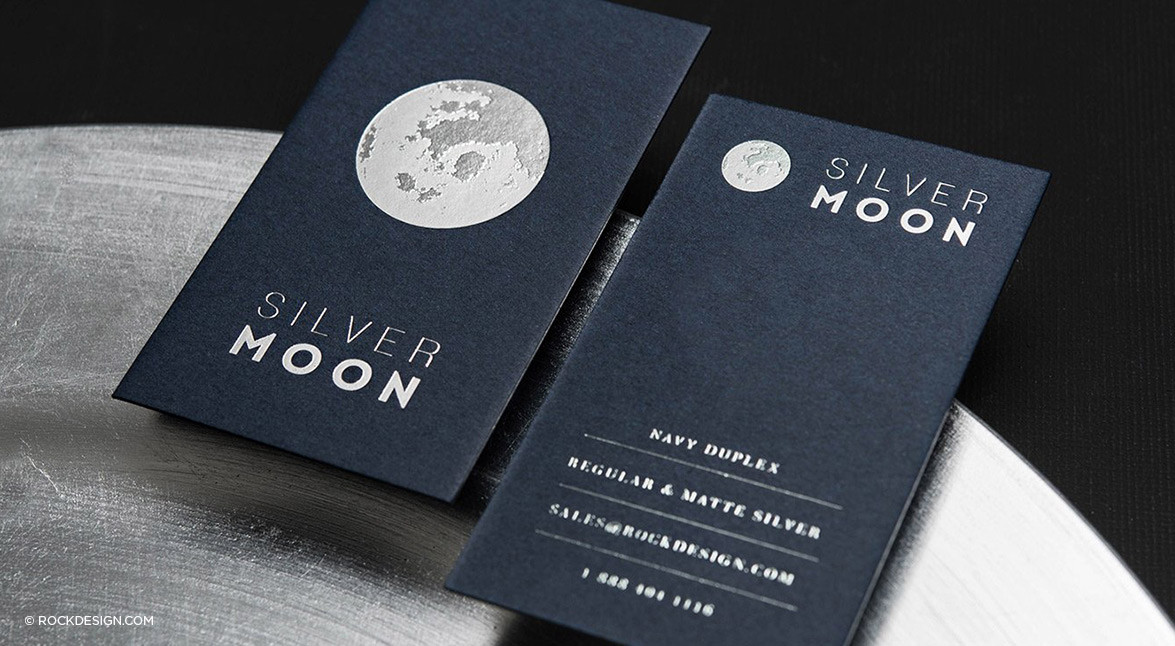

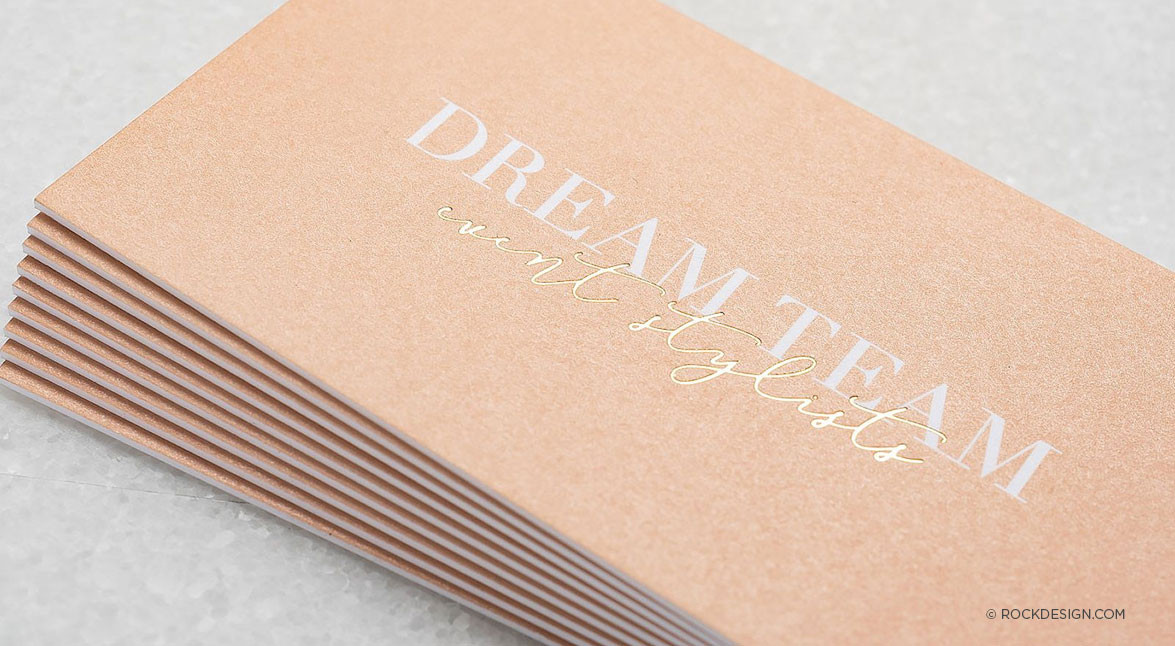

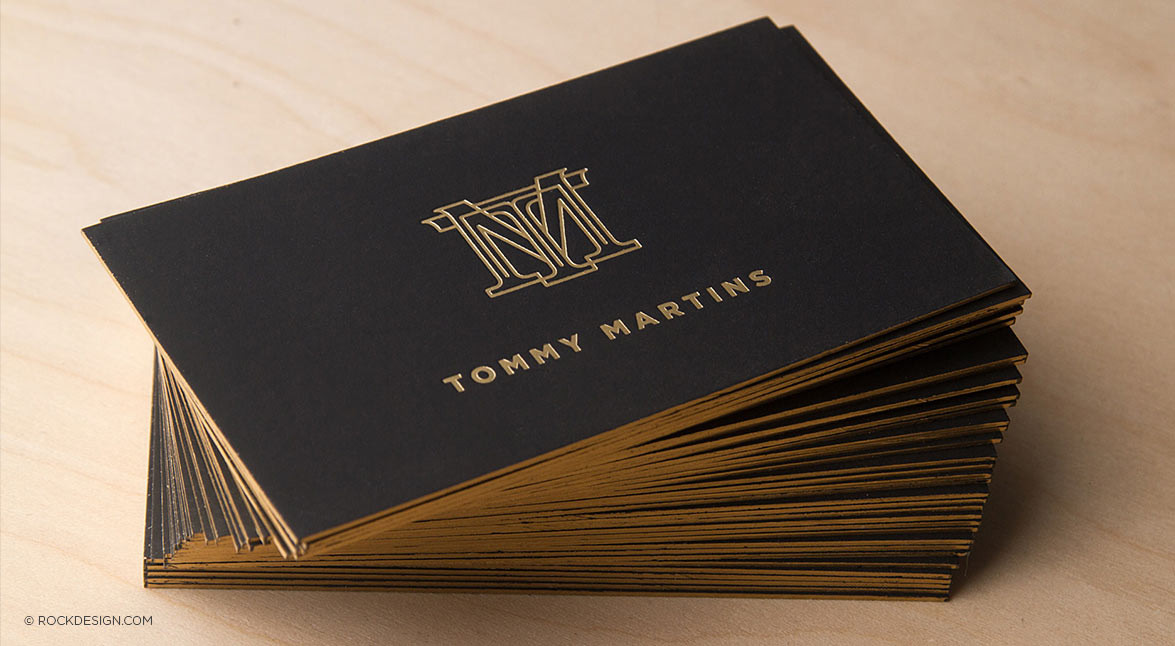

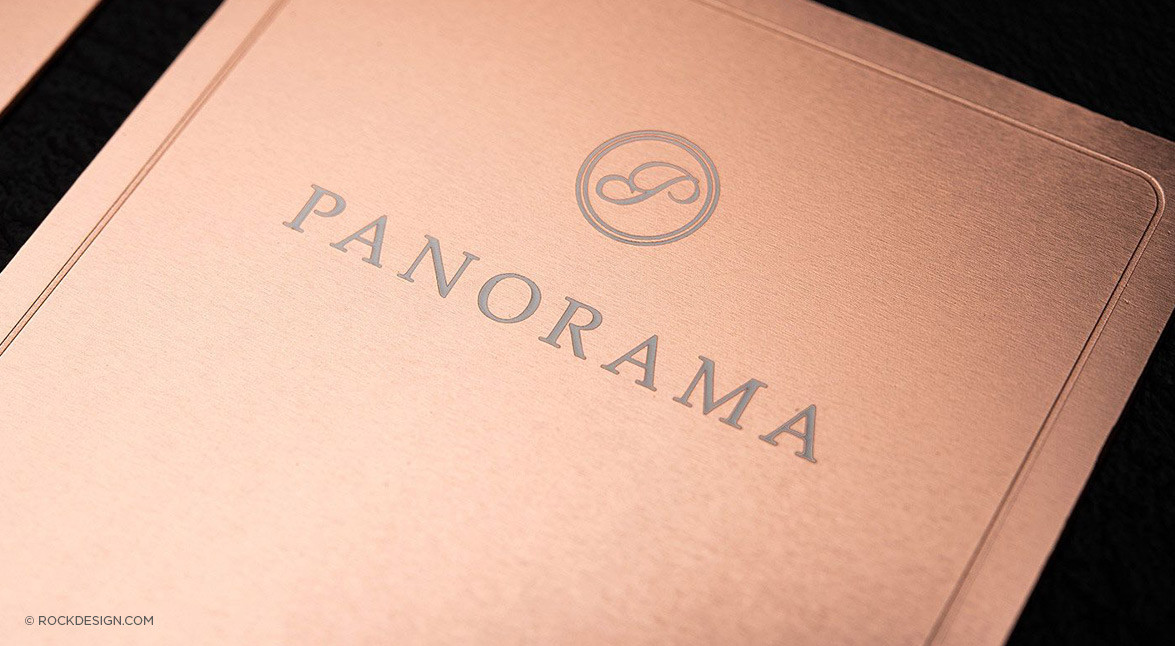

Foil stamping uses a heated plate to apply metallic foil or pigment to the surface of the card. The result is a vibrant and highly saturated metallic appearance. Although this finishing cannot be color matched, we offer a wide variety of colors including; Regular Gold, Regular Silver, Matte Gold, Matte Silver, White, Black, Red, Copper, Rose Gold, Dark Blue, Light Blue, Green, Non-metallic green, Clear, Pearl, Hot Pink, Rose Pink, Holographic and even Rainbow. Our foil stamping is extremely elegant and each plate is created specifically for your business card design.

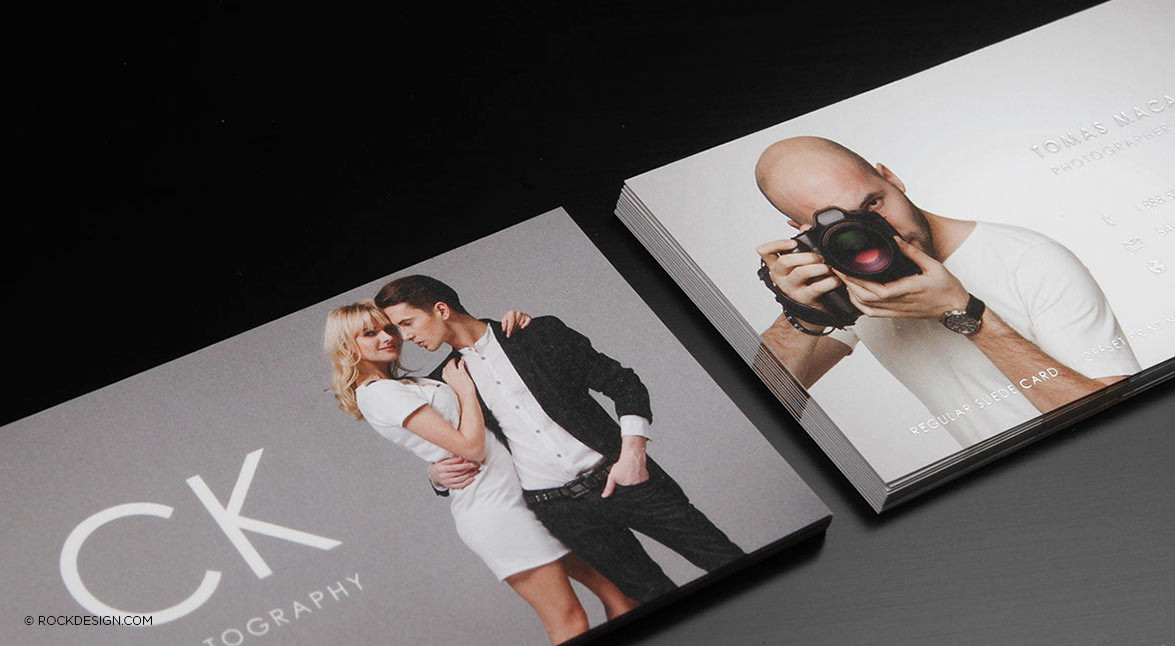

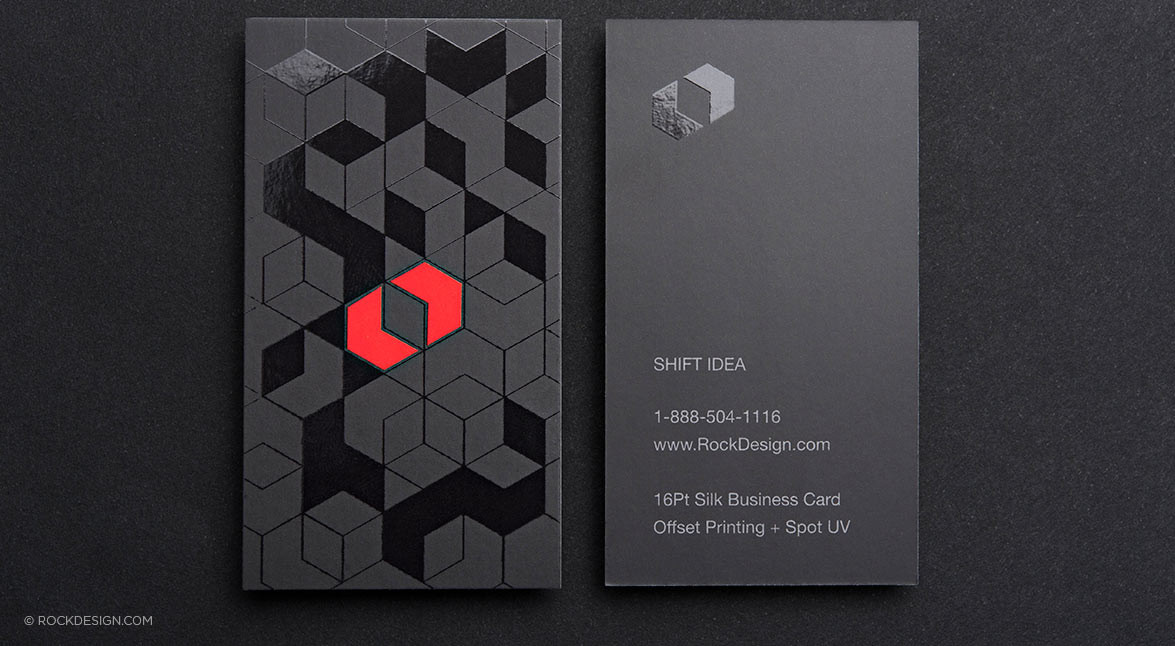

Offset printing is a high-end method of printing that involves applying ink to a surface such as rubber and then pressing it onto the card. This offset process allows for clearer colors, clearer images, and spot color printing. The print quality of offset printing is higher than that of digital printing which is why we do not offer digital printing. Please note the cost of offset printing is not included in the base price of any of our luxury or premium cardstocks. If you require ink printing on any of these stocks, please select offset printing from the drop down menu.

Adding spot color to an order with offset print will facilitate closer color matching, to apply brilliant solid colors to our premium and luxury cardstocks. With the use of Pantone color codes for reference, spot color is ideal if very specific colors are required to be matched for your branding.

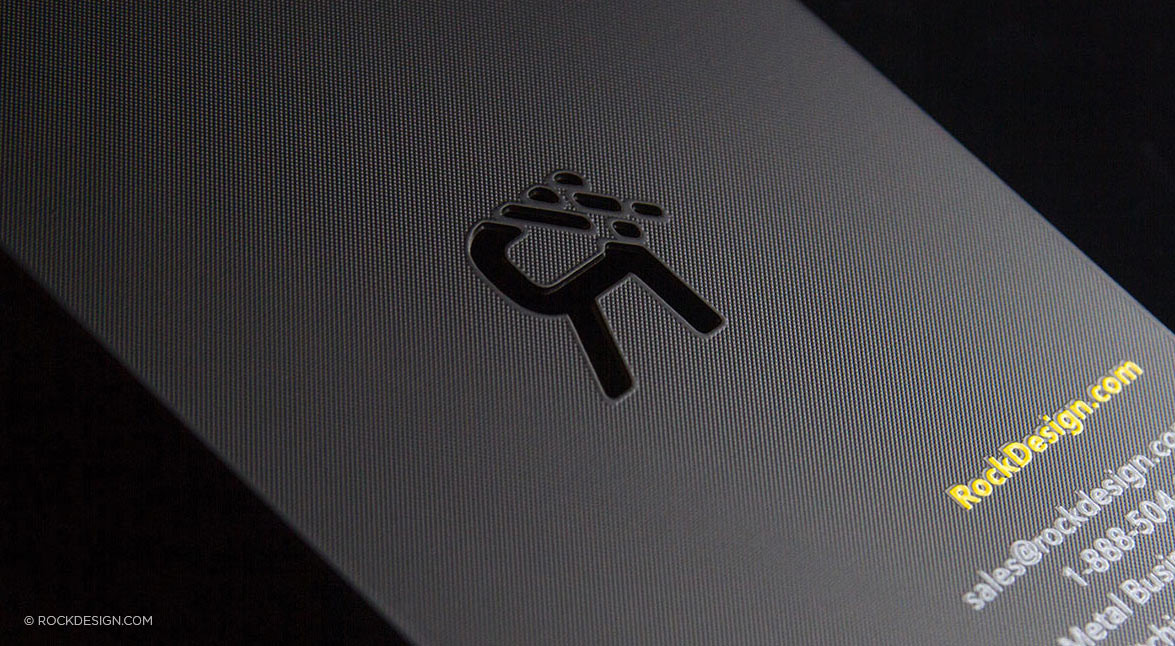

Spot color is a special technique with which we can apply brilliant solid colors to acrylic, carbon fibre and metal cards. On metal it is recommended to be combined with etching, but it can stand alone just as well given the right design. Spot color is the perfect way to add your unique branding to these already exquisite materials.

UV Printing is a form of digital printing which uses ultra-violet light to cure ink to surfaces. Its rapid drying speed while maintaining a high level of detail makes it the superior choice for printing on plastic! It is used to print black, greyscale or any colors, to create text, logos, or even photographs.

Spot UV is a glossy finish that can be applied to any of our laminated stocks. While subtle, this unique finishing adds an element of luster to specific design elements. Please note that this finishing is not available on our uncoated stocks (i.e. hard suede, soft suede, black duplex, triplex, smooth white, etc…)

Thermography is a heat applied process which results in a raised, clear, glossy finish. This finishing creates a particularly remarkable finish that allows the color of what is underneath to shine through. Thermography is an excellent way to enhance printing as well as can be used on darker cardstocks as well.

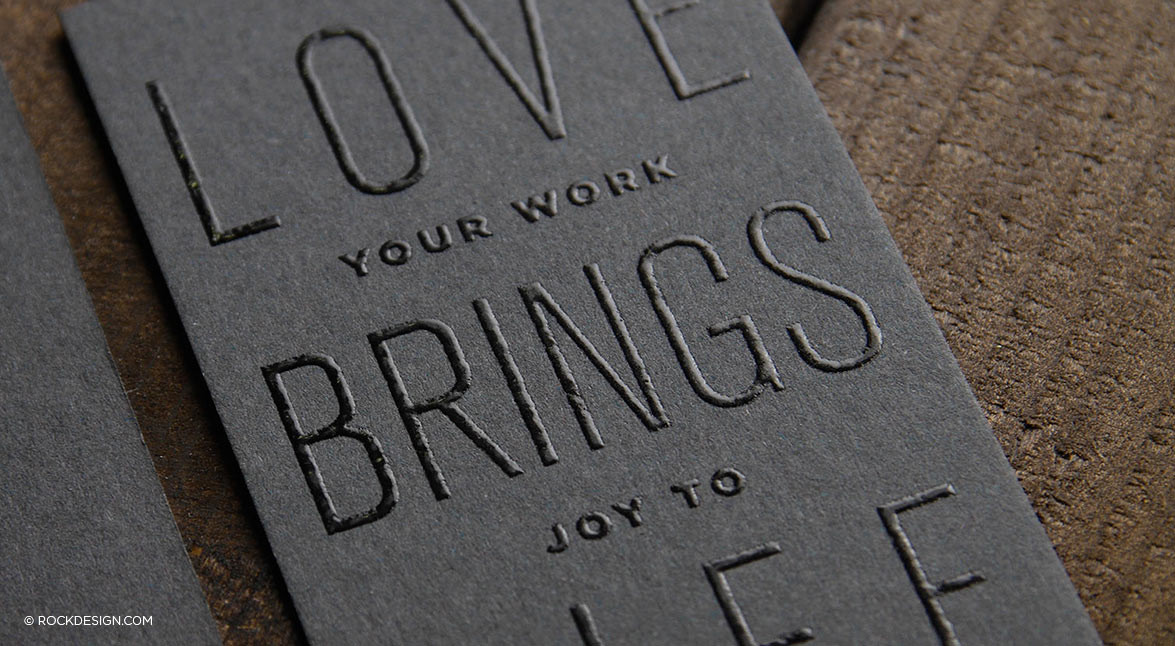

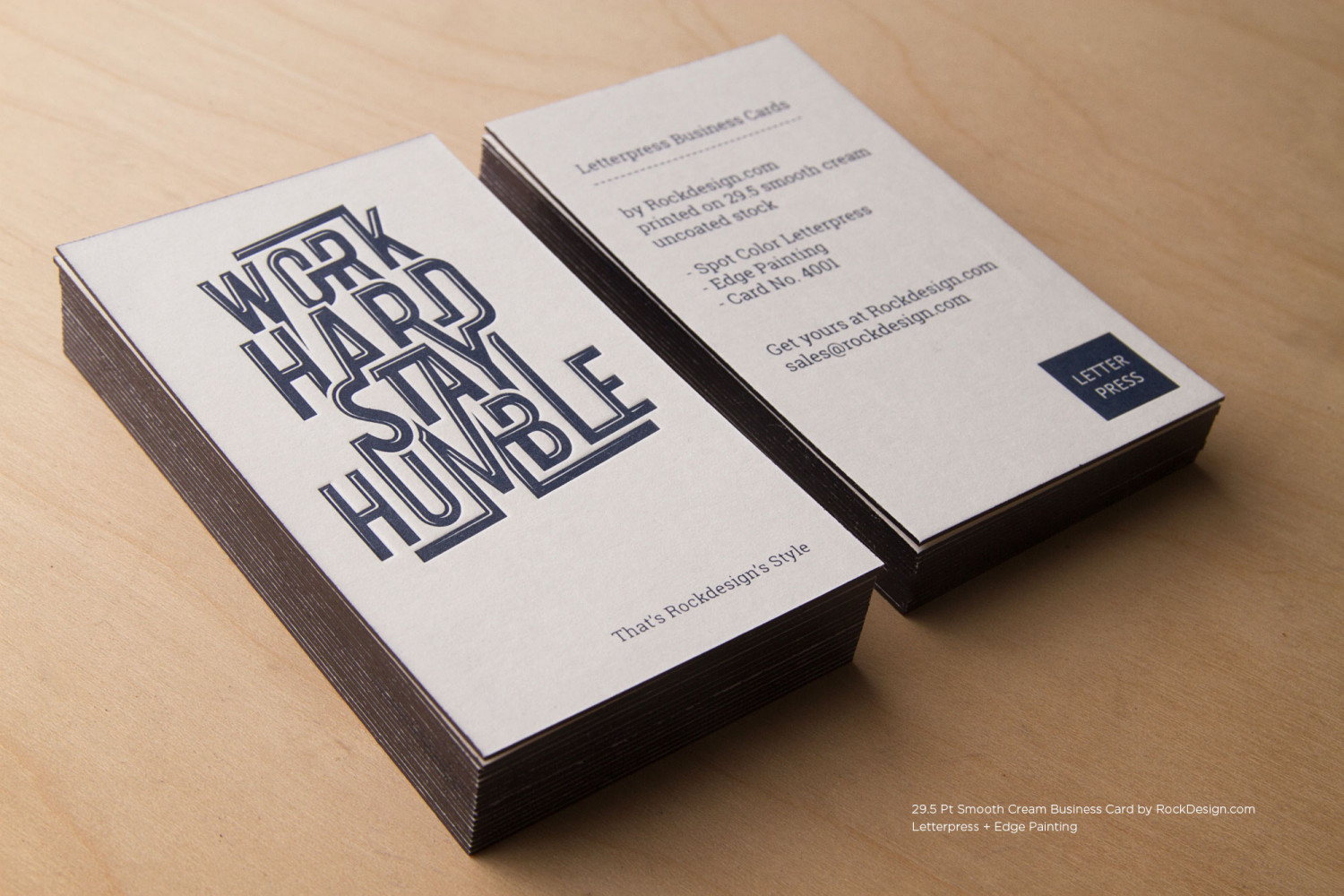

Letterpress is a plate stamping technique where ink and pressure are applied to the cardstock simultaneously. The result is an indented appearance that is filled with a rich, highly saturated ink color. Letterpress is ideal for block colors and is perfect when used on our letterpress stock. This finishing can also be used on our smooth uncoated, and textured cardstocks as well.

Our metallic ink is a form of brilliant metallic printing. This finishing is available in silver, gold or bronze and is ideal for printing text or designs onto a wide variety of our cardstocks!

Considerations:

The appearance of metallic ink will be more opaque on the coated, plastic or metal materials than it is on our uncoated cardstocks, however, it remains an excellent way to add a pop of shine to your design! It is important to note that we cannot colour match our metallic inks and are unable to print gradients.

White ink is an excellent alternative to white foil since it creates a clean, matte finish. This finishing is available on all luxury and premium paper stocks and all plastic stocks apart from the Frost Polyester. White ink is a great option for more intricate and detailed designs and has an especially brilliant finish on our soft and hard suede stocks. Although it is not as opaque as our white foil, the overall finish of white ink is a much more accurate representation of the design.

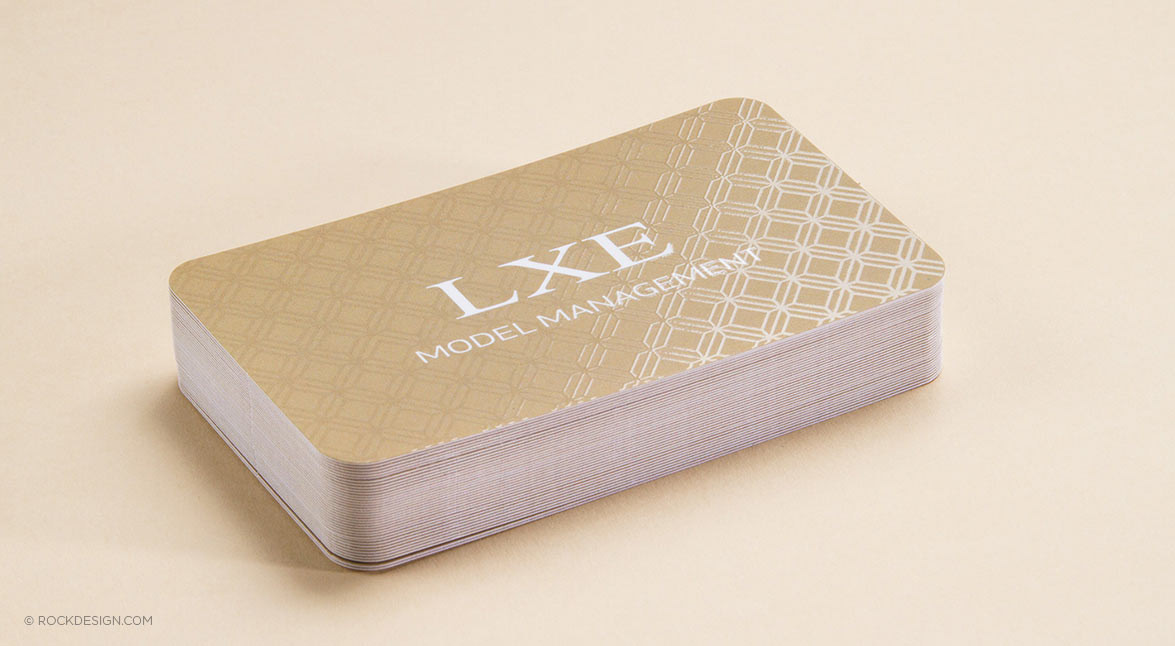

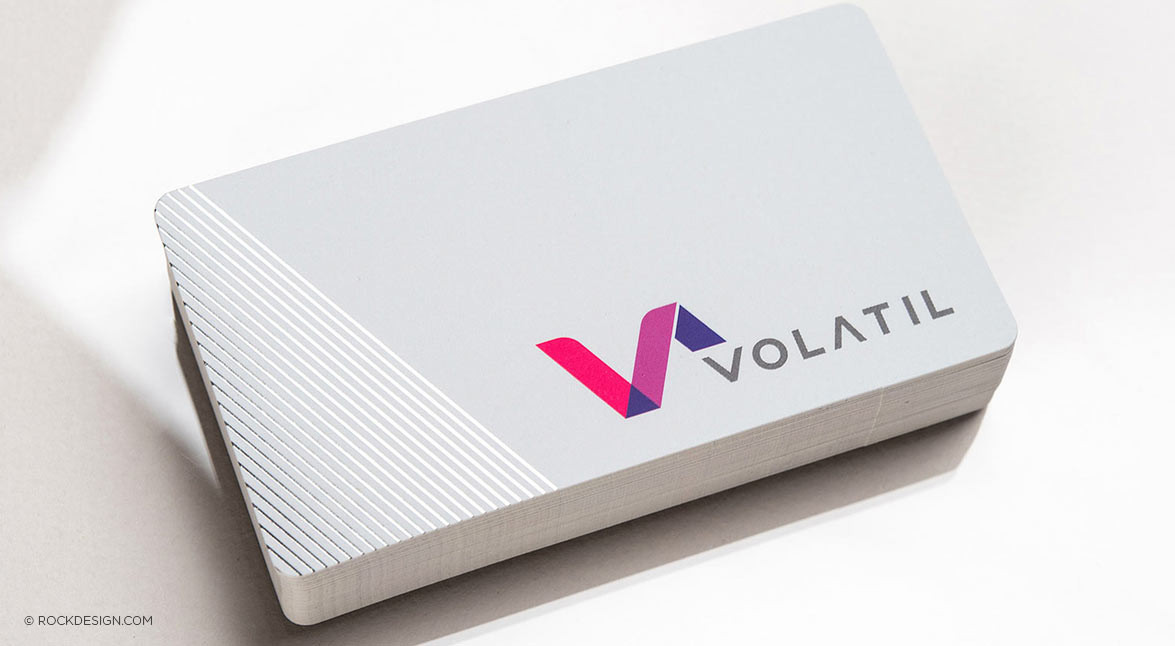

Die-cutting is a process where a metal die is used to custom cut the shape of the paper. It can be used to create a unique size, rounded corners, or a unique shape to suite your design’s needs. Die cutting can also be used to create cut outs on our paper or metal cards.

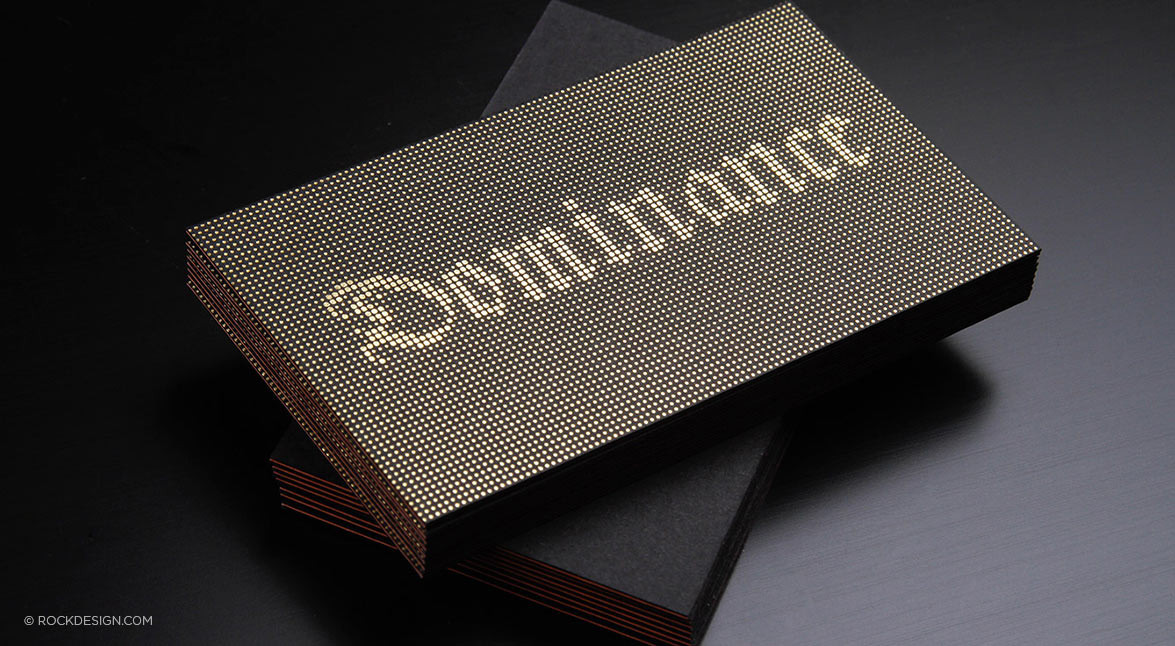

Edge foil is a process where we apply the foil that we normally used for stamping to the edges of the card. The result is a beautiful metallic shine that adds an extra dimension of elegance and luxury to your design. It is available in all of our foil colors to suite your branding needs.

Edge paint is an ideal way to either add a fun pop of color to your design, or to hide the white edges of your design. Edge paint can be color matched to suite your branding needs.

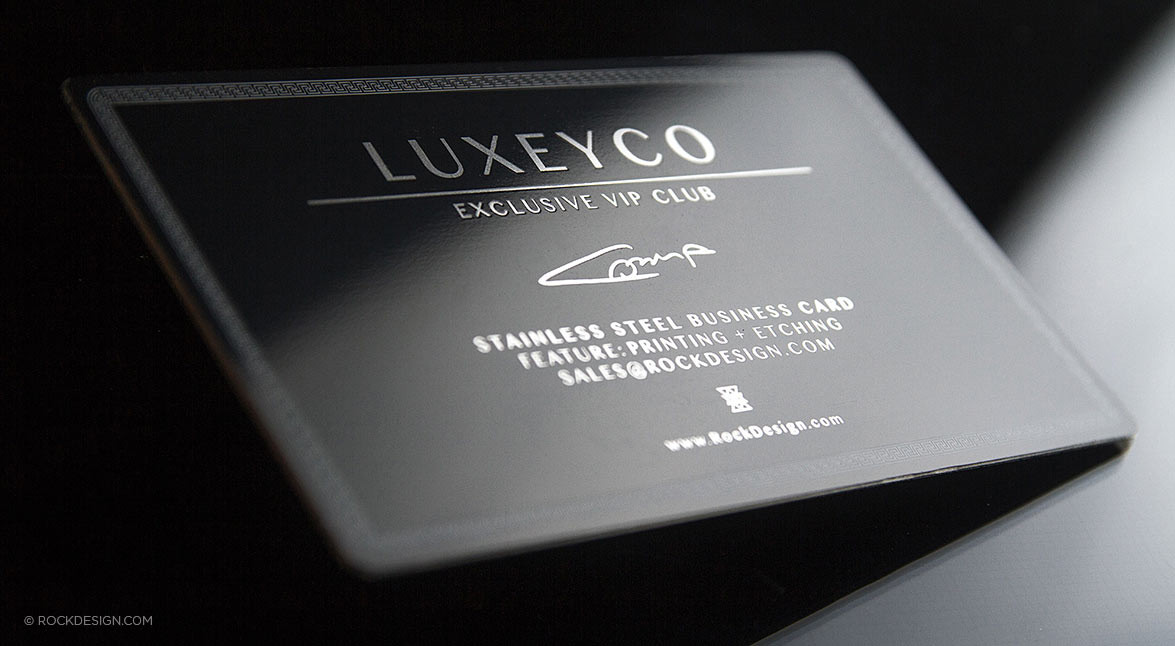

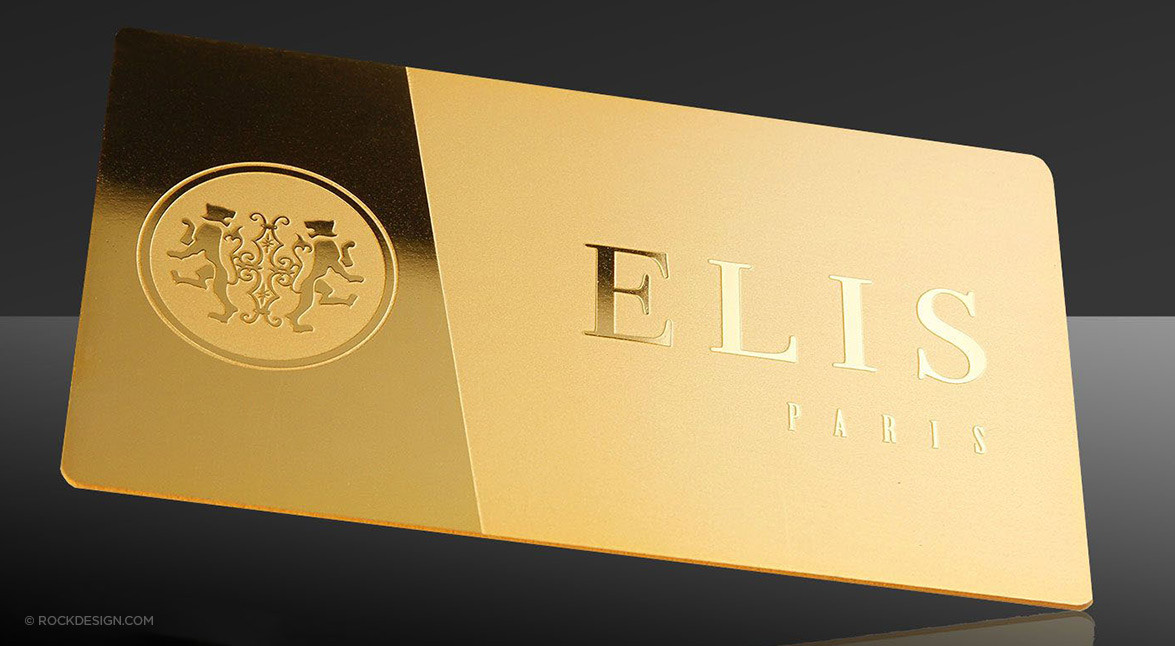

Etching is a process that can be used only on our metal cards. It is used to create a slightly recessed appearance and even creates a matte look when used on our stainless steel cards. Etching is a luxurious and ideal finishing for detailed designs and is beautiful when paired with spot color.

Laser engraving is a process that uses heat to engrave a design element onto the card. The resulting look is dependent on the cardstock selected. On our black duplex uncoated cardstock or our quick metal stock, laser engraving has an intriguing beige/bronze look. On our black metal business cards, laser engraving has a silver look. Laser engraving on our gold metal, stainless steel, and rose gold metal stocks results in a matte finish. Please note that laser engraving should not be applied to mirrored stocks and is not suitable for designs with fine details.

Die cutting is a process where we can customize the shape of your card. This is a great way to make your business cards a unique representation of your brand. We offer both simple and complicated die cuts allowing us to create everything from product tags to unique shapes. Cut through can be used on our paper or metal cards as part of a custom die cut. Die cutting is a unique process so it is recommended that you email your design to sales@rockdesign.com prior to ordering.

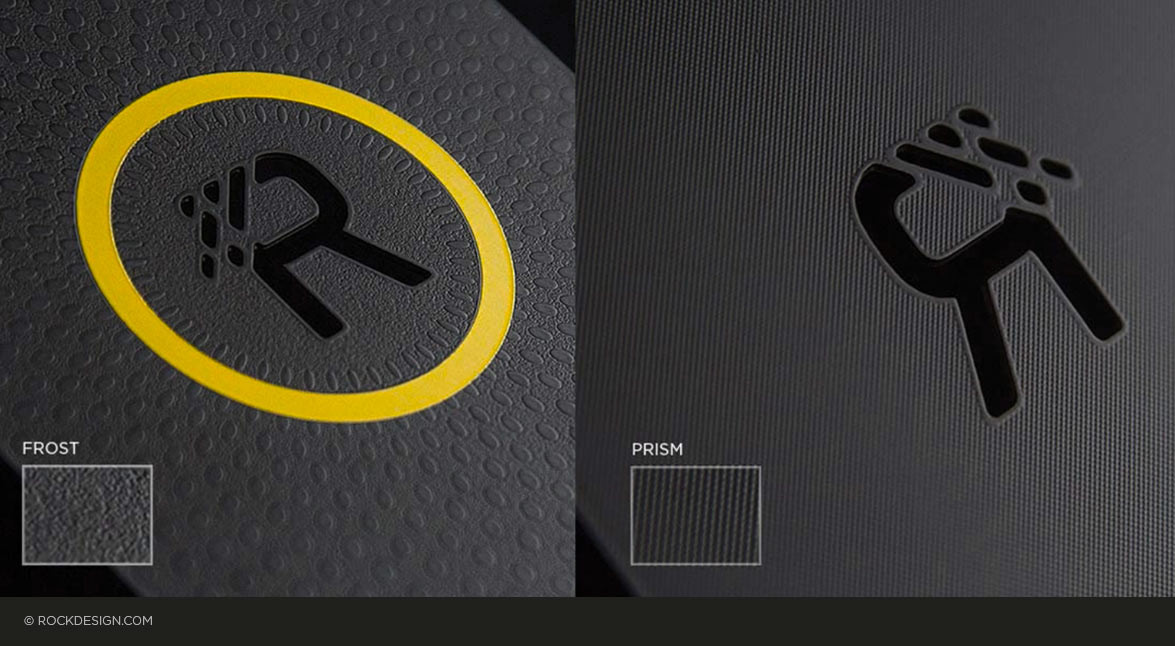

Our exclusive prism and frost finishings are an elegant etching process that is used on our luxury black metal cards to create a fingerprint resistant texture. Prism finishing creates a beautiful micro geometric pattern while frost finishing has an elegant and subtle texture. Opting for our luxury metal business cards with either of these finishings is a superb way to make a bold and confident statement about your company.

Variable data is a way to include unique text, numbers or characters on each of your metal business cards. It can be applied using spot color or laser engraving and is perfect for including membership names or numbers.

A design is considered full-bleed when any element is applied right to the very edge of the card. This will typically require the printing process to be performed prior to trimming the cards to properly execute the design and alignment. Full-bleed designs may also require oversized plates or incur other surcharges, depending on the print feature(s) used.

Thickness refers to the width of the card when examining the edges. We measure the thickness of our cardstocks in points which is is a standard unit of measurement. 1pt is equal to 1/72 of an inch.

Size refers to the dimensions of the business card. The North American standard is 3.5”x 2” however we can produce odd sized cards to meet your needs.

Oversized Plates are required for any designs which use plate stamping techniques that fall within 0.25” of the card edge. These plate requiring techniques include: emboss, deboss, foil stamping, thermography and letterpress. As a larger plate is required to be crafted to accurately complete the print job, a surcharge is applicable. If your stamping design falls with in 0.25” of the edge, please be sure to select this option on our price calculator.

‘Blind’ refers to a print feature that is applied without any additional colour/print feature. In most cases, this will have the blind feature show as the same colour as the cardstock but be manipulated in some other way

Laser cutting is a process which uses a laser to cut our acrylic cards into a unique shape. This finishing is an ideal way to add further personalization to your card order. Within the laser cut feature a custom cut out can also be included.

Original or matte finishing refers to the natural appearance of the stainless steel, gold metal, and rose gold metal stocks. Although it is not as reflective as our mirror finishing, it still has an elegant sheen which is comparable to the appearance of standard high end stainless steel appliances. Original finishing is an excellent option for metal card designs that have large amounts of un-etched material since it is more scratch resistant that our mirror finishing. A different surface finishing can be applied to each side of our stainless steel, gold, and rose gold metal cards, with the restriction of there being only one per side.

Mirror finishing is a beautiful way to create a highly reflective and polished look on our gold, stainless steel or rose gold metal cards. With this finishing the un-etched surface will have an elegant sheen. Mirror finishing is more prone to show scratches and blemishes. This finishing is recommended for use with designs where etching covers a large portion of the surface of the card. A different surface finishing can be used on each side of our metal cards, with the restriction of there being only one per side.

Brushed finishing is one of three surface finishing options we offer for our stainless steel, gold, and rose gold metals, and the only finishing available for our gunmetal, copper, and brushed black metals. This finishing creates a subtle linear pattern on the un-etched surface of the card. This finishing is ideal for clients with designs with both large amounts of etching or large amounts of un-etched surface. A different surface finishing can be used each side of our metal cards, with the restriction of there being only one per side.

Custom emboss is a unique process that allows us to create a raised detail by embossing on one side of the card, but without the reversed impression that typically occurs with standard emboss. Elegant and captivating, it may be exactly what your cards are missing to take them to the next level! With custom embossing, the technique is applied before gluing a duplex or triplex stock together, so the backside design does not have any interference from a reversed impression!

Elevate your designs to new heights of sophistication and visual appeal with Raised Foil printing. Experience the luxurious touch and captivating shimmer of raised foil elements, available in a range of vibrant colors including red, black, green, light blue, white, regular gold, and regular silver. Enjoy the seamless compatibility of raised foil with edge foil and edge paint, allowing you to create truly stunning and unforgettable prints.