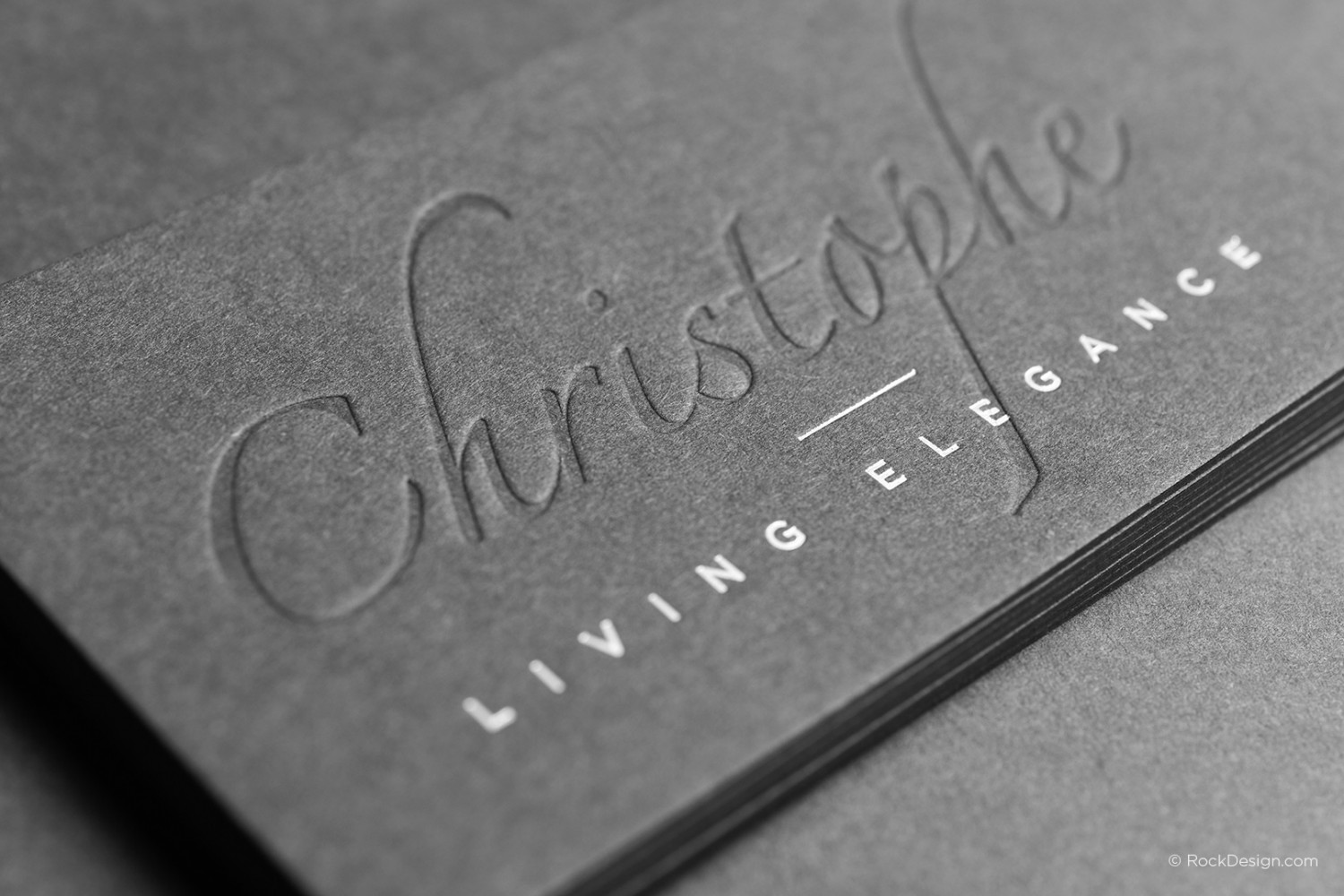

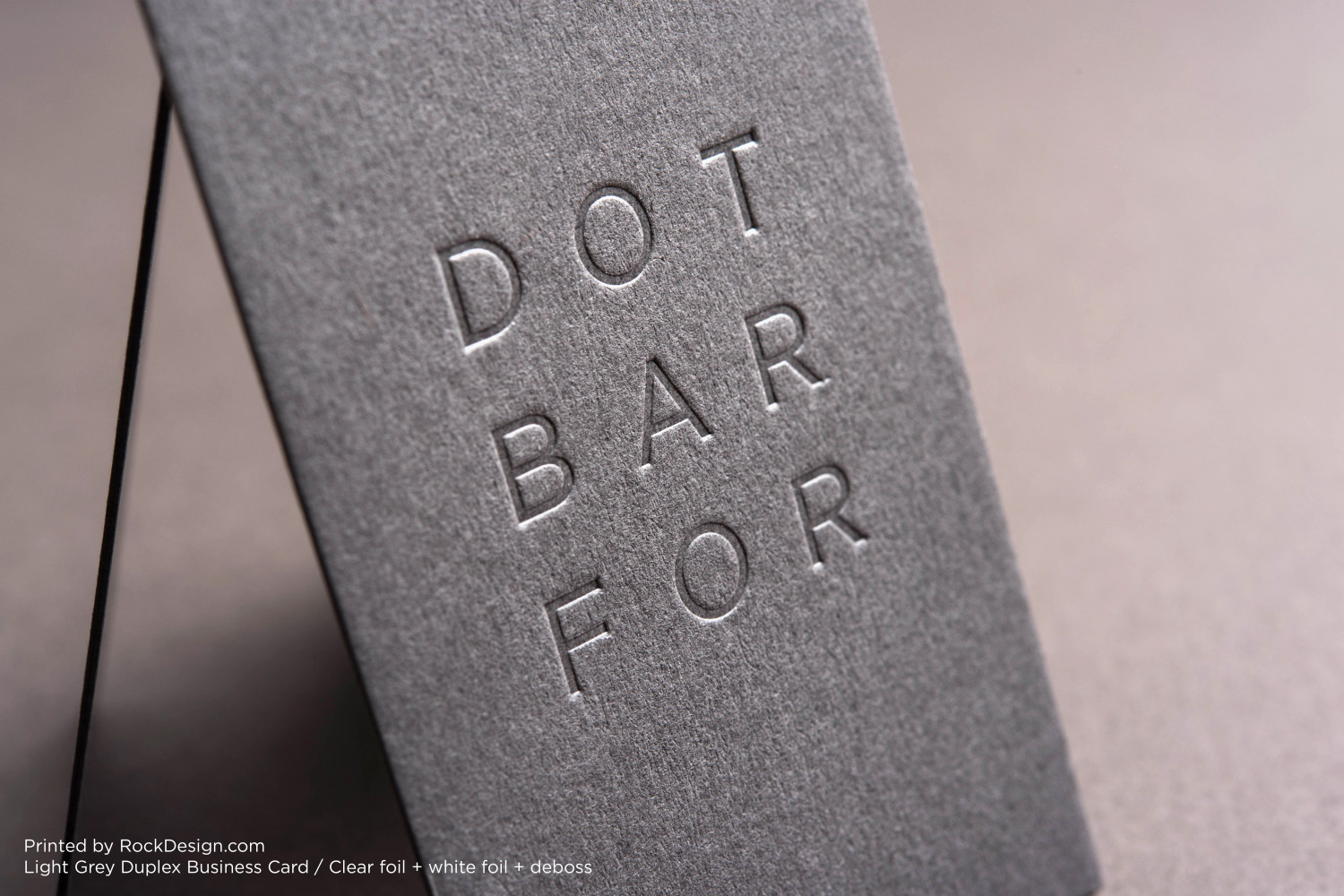

WHAT IS Deboss

Deboss is a plate stamping technique which uses heat and pressure to give an indented appearance to a design. This high-end technique that can be used on our premium and luxury paper stocks to add more definition and dimension to your design. Deboss is a dynamic feature which can be used on its own to create a subtle look called a blind deboss, or we can perform what is called a registered deboss, where the deboss is applied over another print feature such as foil or ink printing. Deboss is not to be confused with letterpress, a similar technique with which ink and pressure are applied at the same time. Deboss is instead a separate step that is in addition to any foil stamping or ink printing. Debossing intends to only push up to halfway through the card, so that it does not leave a complete reversed emboss on the opposite side, however, some unintentional bruising can occur.

DESIGN CONSIDERATIONS

● Fine details may be lost with deboss. Please contact our sales team if you have a highly detailed design so that we can asses it for feasibility.

● Slight pressure marks, bruising, may be left on the reverse side of the card. The extent of this is dependent on the thickness & density of the cardstock, as well as the surface area of the design to be debossed.

● Deboss is available only on paper stocks, except for the following: luxury Soft Suede, premium Silk Laminated or Premium Uncoated, and all classic stocks.

● Deboss can be combined with foil stamping, offset printing, metallic inks & white ink.

● Debossing is ideal for designs with at least a 2mm buffer zone between the deboss and other plate stamping elements. This rule is to ensure that the deboss is as clear and detailed as possible, and to leave the other element unaffected.

● Deboss must have a 2mm buffer zone between it and edge foil or paint.

● Deboss is subject to oversized plates.